Jun. 14, 2024

Securing metal lath properly is essential for ensuring the stability and longevity of plaster or stucco applications. Metal lath provides a strong, durable framework that supports these finishes, making it a crucial component in construction. This article will guide you through the steps of securing metal lath, covering the necessary tools, techniques, and best practices to achieve a reliable installation.

Before installing metal lath, ensure the surface is clean, dry, and free of debris. This preparation step is vital for achieving a secure and stable installation. If the substrate is wood, check for any loose or damaged areas that need repair. For masonry or concrete surfaces, remove any loose particles and fill in significant cracks or holes.

To secure metal lath, you will need the following tools and materials:

Metal lath sheets

Fasteners (nails, screws, or staples)

Hammer or screw gun

Tin snips or metal shears

Protective gloves

Measuring tape

Chalk line or pencil for marking

Choosing the right type of fasteners is crucial. For wood substrates, galvanized nails or staples are suitable. For masonry or concrete, use screws with washers or specialized anchors designed for these materials.

Measure the area where the metal lath will be installed. Use a measuring tape to determine the dimensions and mark the lath sheets accordingly with a chalk line or pencil. Cut the lath to size using tin snips or metal shears, wearing protective gloves to avoid injuries from sharp edges.

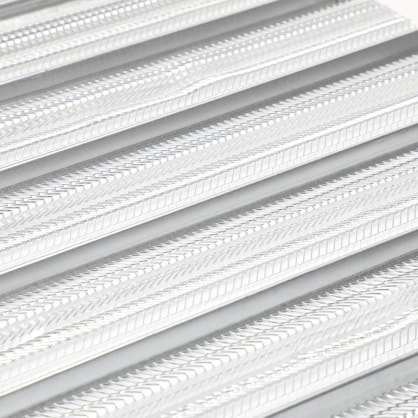

Start at one corner of the surface and position the metal lath sheets with the small diamonds or ribs facing outward. This orientation provides better adhesion for the plaster or stucco. Overlap the edges of the lath sheets by at least 1 inch to ensure a continuous, stable surface. For added stability, overlap the lath at inside and outside corners by at least 6 inches.

Recommended article:For wood substrates, secure the metal lath using galvanized nails or staples. Space the fasteners approximately 6 inches apart along the edges and every 12 inches in the field of the lath sheet. Ensure the fasteners penetrate the wood by at least 3/4 inch. Start at the center of the lath sheet and work outward, keeping the lath taut to prevent sagging or bulging.

For masonry or concrete surfaces, use screws with washers or specialized masonry anchors. Pre-drill holes in the substrate if necessary, ensuring they are spaced about 6 inches apart along the edges and every 12 inches in the field of the lath sheet. Insert the screws or anchors and tighten them to secure the lath. As with wood substrates, start at the center and work outward, maintaining tension in the lath.

Corners and edges require extra attention to ensure a secure and stable installation. Use corner lath or corner bead to reinforce these areas, attaching them with the same type of fasteners used for the main lath sheets. Overlap the corner lath or bead with the main lath sheets by at least 6 inches, securing them firmly in place.

Once all the metal lath is secured, inspect the entire installation to ensure there are no loose areas, gaps, or bulges. Make any necessary adjustments by adding additional fasteners or repositioning the lath as needed. A thorough inspection at this stage can prevent issues later when applying plaster or stucco.

With the metal lath securely in place, you can proceed with applying the plaster or stucco. Follow the manufacturer’s instructions for mixing and applying the material, ensuring it adheres properly to the lath. The securely fastened lath will provide a strong, stable base, ensuring a durable and long-lasting finish.

Securing metal lath is a critical step in ensuring the success of plaster or stucco applications. By following these detailed steps and using the appropriate tools and materials, you can achieve a secure and stable installation. Properly installed metal lath provides the necessary support for a durable and high-quality finish, whether for interior or exterior applications.

4o

162

0

0

All Comments (0)

Previous: None

Next: None

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments