Jul. 04, 2024

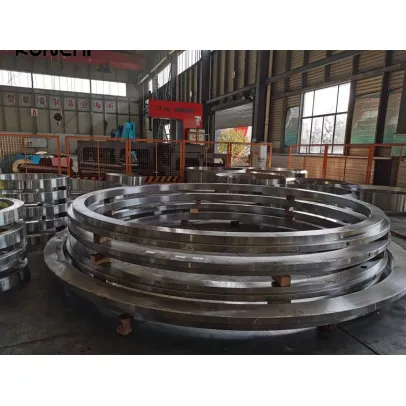

Rolling ring, also known as ring forging rolling forming or reaming, is a plastic processing technology that expands the diameter of ring forgings, reduces the wall thickness, and gradually forms the cross-section profile with the help of ring rolling equipment-ring rolling machine (also known as rolling forming machine or reaming machine). Rolling ring is a continuous local plastic forming process. Compared with the overall die forging forming process, it has significant technical and economic advantages such as greatly reducing equipment tonnage and investment, low vibration and shock, energy saving and material saving, low production costs, and high mechanical properties. It is a bearing ring, gear ring, flange ring, train wheel and hoop., Advanced manufacturing technology of various types of seamless ring forgings such as gas turbine and aerospace engine casing, sealing ring, installation edge, etc., has been increasingly widely used in many industrial fields such as construction machinery, transportation, shipbuilding, petrochemical, aerospace, atomic energy, etc.

1. Classification of rolling rings

1) Radial rolling forming

The principle of radial rolling and forming of annular forgings, the drive roller is the active roller, which simultaneously performs the rotating rolling and forming movement and the linear feed movement; the core roller is the passive roller, which is the driven rotating rolling and forming movement; the guide and signal rollers are both freely rotatable driven rollers. Under the action of the driving roller, the annular forging is continuously and locally plasticized by the rolling forming hole shape composed of the driving roller and the core roller, so that the wall thickness of the annular forging is reduced, the diameter is expanded, and the cross-section profile is formed. When the annular forging is rotated after multiple rolling and forming and the diameter is expanded to a predetermined size,When the outer circular surface of the ring forging is in contact with the signal roller, the drive roller stops the linear feed movement and returns, and the ring rolling process ends. The guiding movement of the guide roller ensures the smooth movement of the ring forgings during rolling and forming.

The radial rolling forming equipment for ring forgings has a simple structure and is widely used in the production of small and medium-sized rolling rings, but the surface of the ring forgings formed by rolling often has pit defects.

2) Diameter one axial rolling forming

In order to improve the quality of the end face of the rolled ring forgings and the ability to form complex cross-sections, on the basis of the radial ring rolling equipment, a pair of axial end face rolling rollers are added to roll the radial and axial sides of the ring forgings at the same time, so that the ring forgings produced by the radial rolling and forming are formed at the same time.The depression on the end face is repaired and leveled due to axial rolling. Axial end face rolling and forming can also make the ring forgings obtain a complex cross-sectional contour shape. The diameter of the annular forging is rolled axially, the drive roller is rotated and rolled to form, the core roller is fed radially and linearly, and the end face rolling roller is used as the rotating end to form the rolling movement and axial feed. In the axial rolling and forming of diameter one, the radial wall thickness and axial height of the annular forging are reduced, the inner and outer diameters are expanded, and the cross-section contour is formed by continuous local plastic deformation. When the annular forging is repeatedly rolled and formed so that the diameter reaches a predetermined value, the radial feed of the core roller and the radial feed of the core roller.The axial feed of the end face roller stops. The diameter of the ring forgings is rolled in one axial direction and the deformation is over. Compared with radial rolling forming equipment, diameter-to-axial rolling forming equipment has a complex structure and is mainly used for the production of rolling rings with large and complex cross-sections.

2. Rolling ring application

Rolling rings are suitable for the production of Custom ring forgings or ring blanks of various shapes, sizes and materials. The materials of ring forgings are carbon steel, alloy steel, aluminum alloy, copper alloy, titanium alloy, diamond alloy, nickel-based alloy, etc. Common rolling-formed ring forgings include bearing rings, gear rings, train wheels, casings, sealing rings and mounting edges on gas turbines and aviation engines. The largest rolled-formed ring forging is a nuclear reactor container with a diameter of 10,000mm and a height of 4,000 mm.

286

0

0

All Comments (0)

Previous: How to Identify and Fix Block Forging Defects

Next: None

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments